Easy Homemade Remedies with Rosewater for Luscious Hair and Glowing Skin

Today, with the growth of industry, many organizations are faced with a bulk of raw materials and products in their warehouses. For this reason, the ease of moving these materials and products is one of the top priorities for warehouse managers. Since goods are usually placed on pallets and stored in warehouse shelves along with the pallets, the presence of pallet handling equipment and safe and secure pallet transportation tools in the warehouse is essential.

To select suitable equipment for transporting different loads, attention should be paid to the type of load and its weight. Some pallets stored in warehouses are very heavy and sensitive. Therefore, handling and loading them should be done with special equipment or machinery and require special attention.

Pallet Transport Equipment

The first thing that comes to mind when talking about pallet handling equipment in factories and warehouses is a forklift. Forklifts have been traditionally used for unloading and loading various loads, especially pallets. Nowadays, there are various types of forklifts such as manual forklifts, electric forklifts, overhead forklifts, and workshop forklifts. We will become more familiar with these pallet transport equipment below.

If you are interested in learning more about pallet storage, you can read the article on pallet storage methods.

Manual Forklift

A manual forklift or hand pallet jack is one of the most commonly used types of forklifts in factories, warehouses, and even small workshops. This tool is mainly used for loading and unloading pallets. Usually, manual forklifts are chain-operated.

Electric Forklift

Compared to manual types, electric forklifts can handle heavier loads. These forklifts are used in workshop and factory environments. Electric forklifts operate on three-phase power and are usually available in single-speed and dual-speed models. The weight limit they can carry ranges from half a ton to 50 tons and varies.

Overhead Crane

One of the oldest and most important pallet transport equipment is the overhead crane. The history of overhead cranes dates back to ancient Egypt where they were used to transport large stone blocks for building the Egyptian pyramids. Currently, various types of overhead cranes are available in the market, including single-girder, double-girder, gantry, overhead portal, column, or span cranes.

Workshop Crane

Workshop cranes are used in warehouses or small workshops due to their shorter length compared to other types of cranes. These cranes are also used on uneven and non-road surfaces. Workshop cranes are steerable as each of their four wheels is steerable. Additionally, they have large off-road tires.

Forklift - the most advanced pallet transport equipment

One of the most essential pallet transport equipment is the forklift. Forklifts are both ancient and sophisticated tools for moving pallets and various loads. Forklifts come in manual, electric, gas, diesel, and gasoline-powered variations. Stackers are another type of forklift that, due to their small size, can move between warehouse shelves.

The lifting capacity of forklifts starts from 1.5 tons and goes up to 50 tons or more. It is worth mentioning that higher lifting capacity forklifts come with higher prices.

Stacker

Stackers are important pallet handling equipment in hygienic environments, mostly used in pharmaceutical factories where the space needs to be sterilized. One of the main features of stackers is their ability to move pallets at heights, which is very practical in shelved warehouses. There are three main types of stackers:

Manual Stacker: Only moves on smooth surfaces and requires human force.

Semi-Electric Stacker: The semi-electric stacker operates with 12 or 24-volt car batteries, but human force is needed to move this vehicle. It is worth mentioning that this type of stacker is more suitable for semi-heavy loads up to a capacity of 1.5 tons.

Electric Stacker: Electric stackers are powered by 24-volt car batteries with 225 ampere-hours. In this vehicle, all lifting and movement stages are done by electric power. These stackers also come equipped with a platform or a station for the operator to stand and have protective guards. Electric stackers are known as pallet transport equipment for loads up to 2 tons. These stackers move faster than manual and semi-electric types in workshop and warehouse environments. With skill acquisition by the operator, the speed of operation of stackers is higher than forklifts.

Manual Pallet Truck:The simplest type of pallet truck is the manual pallet truck. This vehicle is used for moving small lightweight objects. High weights can cause the pallet truck to topple over. Manual pallet trucks are used for carrying goods in warehouses, shops, and small workshops. Other types of pallet trucks include pallet jacks and manual stackers.

Reach Truck: Another pallet transport equipment in warehouses is the reach truck. The popularity of the reach truck lies in its high maneuverability in narrow spaces. With a smaller turning radius, the reach truck has become a preferred option for warehouses. The standing position for the driver widens their field of vision. Furthermore, the speed of mounting and dismounting for the driver in this vehicle is higher than in other seated equipment.

Hand Pallet Jack

A hand pallet jack is one of the pallet handling equipment used for moving and lifting various tools in different locations such as warehouses, factories, cold storage facilities, and other places. The pallet jack is a useful tool for carrying various loads on pallets in small environments like shops, warehouses, and pharmacies. This device is also designed and produced for larger environments such as factories and workshops in various configurations suitable for their specific usage. The pallet jack is also known by other names such as pallet truck, manual forklift, and pallet lifter.

Electric Pallet Jack

The system of this type of pallet truck is entirely electric. This means the lifting and movement operations of the pallet truck are powered by an industrial-grade 24-volt, 225-amp-hour battery supply and electric motors for motion and pump controlled through electronic boards and a fully ergonomic steering handle. This machine is also recognized in the Iranian industry under other names such as electric forklift, electric lifter, electric pallet stacker, and electric jack. These pallet handling equipment are available in the market in two types: with or without a platform.

The electric pallet jack without a platform does not have a standing platform for the user and the only difference from a manual pallet jack is that it is electric. However, in the case of an electric pallet jack, there is a platform for the user to stand on. This allows the user to have better control over the positioning of pallet loads. These equipment are suitable for transporting pallets weighing up to 2.5 tons.

High Strength Against Heavy Weights

The importance of high-strength pallets against heavy weights cannot be overstated, as they form the backbone of efficient transportation and...

The Standard Pallet Size In Various Industries

The standard dimensions of a pallet, also known as pallet dimensions, are very important based on the packaging dimensions of...

Enhancing Product Transport and Storage

In today's globalized economy, the efficient transportation, handling, and storage of products are essential for businesses to remain competitive. However,...

Environmental Impacts Of Pressed Pallets

Pressed pallets are recognized as one of the newest inventions in the transportation industry that pay special attention to environmental...

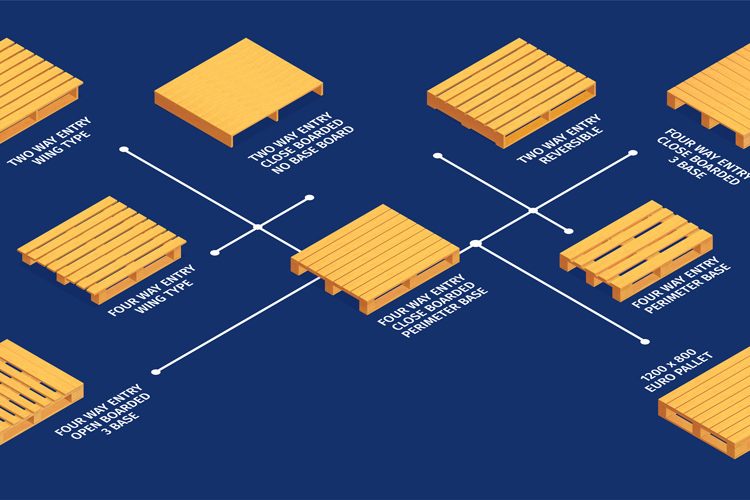

Familiarity With Different Types Of Pallet Designs

In addition to the diversity in the material and dimensions of pallets, there are other differences between different types of...

Buying or renting pallets? Which work is better?

When it comes to the logistics and storage industry, the decision between buying and renting pallets is crucial and can...

Signs Of Pallets And Their Meanings?

There are around 100 standard sizes of pallets in the world. Therefore, the diversity of available pallets from a technical...