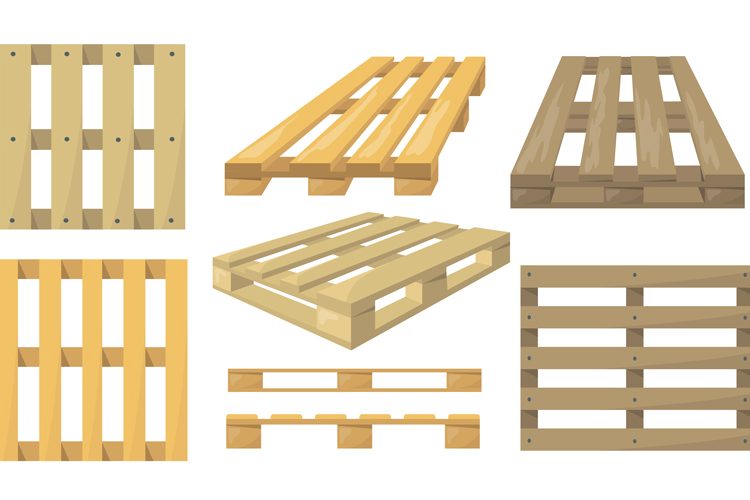

In addition to the diversity in the material and dimensions of pallets, there are other differences between different types of pallets, and that is the structure of the pallet. Different industrial pallet models have different applications and are used for specific industries and situations. In general, based on the manufacturing materials, there are three main types of pallets in terms of structure: wooden pallets, pressed wood pallets, and plastic pallets.

Wooden pallets are the primary type of pallets and are still in circulation in warehouses and transportation industries for moving goods. Despite the common use of wooden pallets in the past years, they have rapidly been replaced by plastic pallets and recently by pressed wood pallets. However, the design of pallets varies depending on the material. Additionally, each type of pallet can have distinct designs for different uses.

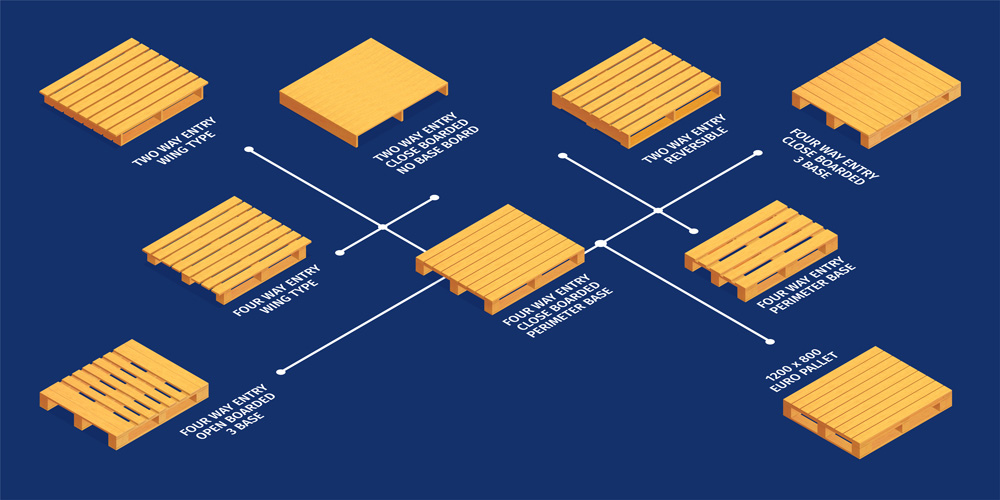

Types of industrial pallets in terms of structure

Design specialists have created various types of pallets, and we will introduce you to six common styles seen in the transport sector.

If you want to learn more about pallets, read this article: What is a Pallet? Introduction to different types of pallets for transportation.

- Stringer Pallets

One of the simplest pallet designs is the stringer design. Stringer pallets are constructed using a sandwich design, where the top and bottom deck boards are separated by strings or boards. These strings act as cross beams that uniformly distribute and carry the weight, contributing to the pallet's load-bearing capacity. Load-bearing weight is vital for pallet durability.

While stringer pallets can be designed in various sizes, the most common size for stringer pallets is 100 by 110 centimeters. The most common style for stringer pallets is uniform design. This allows forklift blades to have easy access from both the front and back for moving the pallet.

In some cases, stringer pallets can have cut or notched sides, allowing forklifts and pallet jacks to access them from all four sides. Compared to other pallet styles, stringer pallets are generally not as durable and are not suitable for transporting heavy loads. However, this largely depends on the quality of the pallet's construction.

- Block Pallets

Block pallets are similar to stringer pallets in that they are constructed using a sandwich design. In block pallets, 9 to 12 blocks are placed between the top and bottom decks of the pallet. The blocks are positioned at each of the four corners of the pallet and, in some cases, one to three additional blocks are placed in the center of each side of the pallet, acting as central load-bearing points.

Block pallets are considered four-way pallets as they are accessible from all sides by forklifts and pallet jacks. Block pallets can be designed with bottom deck boards or open decks. Typically, block pallets are more durable than stringer pallets, but this can vary based on construction quality and materials. Block pallets can be made of wood, plastic, or metal.

- Double-sided Pallets

Double-sided pallets are another type of industrial pallet design where the pallet has a deck on top and a deck on the bottom. Double-sided pallets are designed to be more durable, with a deck on both the top and bottom allowing for uniform weight distribution and increased strength. Double-sided pallets can be reversible or non-reversible.

Reversible double-sided pallets are designed to be loaded on both top and bottom sides as the decks are identical. Non-reversible double-sided pallets have the bottom deck less durable than the top deck, allowing placement in only one direction.

- Two-way Pallet

A two-way pallet is one type of double-sided pallet design. These pallets have a deck on both the top and bottom sides of the pallet. However, the decks extend beyond the edges of the pallet or stringers, giving the pallet a winged appearance. Two-way pallets are usually reversible pallets. However, if they have cutout or notches, they can also be used as four-way pallets.

Depending on the structure and design, two-way pallets may be reversible or non-reversible. Two-way pallets come in standard and non-standard sizes and are usually made of wood, but they can also be made of plastic.

- Solid Deck Pallet

The design of a solid deck pallet is such that it is constructed with a solid top deck (one-piece and flat) and without notches. Solid deck pallets are usually made of wood, with the deck material being a solid sheet of plywood. Solid deck pallets can also be made of plastic or metal. Solid deck pallets are suitable for warehouses that transport smaller items as the one-piece and flat design prevents objects from slipping through gaps.

Many companies prefer solid deck pallets for their cargo transport as they have a one-piece design, making transportation easier compared to other types of pallets.

- Two-legged Pallet

The design structure of a two-legged pallet is similar to a block pallet. The difference is that a two-legged pallet does not have a bottom deck, and the top deck rests only on two legs. Since these pallets lack sufficient strength, they are only used for light loads. However, this type of pallet is not very common and is less seen in the transportation industry.

Design Structure of Wooden Pressed Pallet

The design structure of a wooden pressed pallet is one-piece. Unlike traditional wooden pallets, it is not made up of different components. The primary materials for this type of pallet, mainly crushed waste wood, are mixed with a special adhesive and poured into a mold. Then, a hot press shapes the pallet to withstand weight and ensure ease of transportation. The design structure of pressed pallets can be customized to meet specific requirements for weight-bearing and ease of handling.

Pressed pallets are usually designed to allow handling from all four sides, and a pallet jack or forklift can be placed under these pallets from any side for transportation.

Buying or renting pallets? Which work is better?

When it comes to the logistics and storage industry, the decision between buying and renting pallets is crucial and can...

Environmental Impacts Of Pressed Pallets

Pressed pallets are recognized as one of the newest inventions in the transportation industry that pay special attention to environmental...

High Strength Against Heavy Weights

The importance of high-strength pallets against heavy weights cannot be overstated, as they form the backbone of efficient transportation and...

The Standard Pallet Size In Various Industries

The standard dimensions of a pallet, also known as pallet dimensions, are very important based on the packaging dimensions of...

Equipment For Pallet Handling

Easy Homemade Remedies with Rosewater for Luscious Hair and Glowing Skin Today, with the growth of industry, many organizations are...

Enhancing Product Transport and Storage

In today's globalized economy, the efficient transportation, handling, and storage of products are essential for businesses to remain competitive. However,...

Signs Of Pallets And Their Meanings?

There are around 100 standard sizes of pallets in the world. Therefore, the diversity of available pallets from a technical...